by Gordon Young, FoodStream Pty Ltd, Australia and Dennis Forte, Dennis Forte & Associates, Australia

First published in International Aquafeed, March-April 2015

Extrusion technology provides a number of major benefits over the more traditional pellet milling processes commonly used for aquaculture feeds. In particular, extrusion can provide a much higher degree of control over the “cook” achieved, as well as better control of the product density (therefore controlling the floating/sinking characteristics).

But extrusion is a very complex process – and we only have “indirect” control over that process. That is, we have full control over some variables – eg screw speed and amount of water added. But there are other inputs over which we have “limited” control. For example, we specify a formulation, and within limits we control the specifications of ingredients that go into it – but ingredients do vary, so our process needs to cope with “normal variation”. We set up the extruder and die to a known configuration – but the machine and the die-plate wears, so that over time the process changes.

In addition, we never get just one parameter changing during extrusion – if ingredients vary, it doesn’t just change the final product composition – it changes the rheology of the mix and therefore changes how the melt moves through the extruder and the die, which in turn affects the residence time and temperature developed in the melt, which changes degree of cook and expansion – and therefore affects digestibility and floating/sinking characteristics. Within this complex relationship, we need to achieve consistency – of nutrition, of digestibility, of physical characteristics. It is the cumulative effect of these parameters which ultimately determine the feed conversion ratio (FCR) for the product.

So to use extrusion effectively – and take full advantage of the opportunities offered by the technology – the extrusion process needs to be properly understood. This article discusses just a couple of the issues relating to successful extrusion of aquafeeds.

Extrusion chemistry & aquafeed ingredients

In the area of ingredients, the aquafeeds industry faces a series of contradictions. Marine meals provide the best nutritional basis, but are increasingly difficult to obtain and are therefore expensive. Selected plant sources of protein can provide required proteins, but tend to come with fibre and starch which can interfere with the extrusion process and affect digestibility. We generally require very high fat (energy) contents in the feeds – but high fat levels are a problem in extrusion. Following are some basics of “extrusion chemistry” that relate to the way we design aquafeed extrusion processes:

Starch

Many fish species do not tolerate starch – especially uncooked starch. But starch comes with many of the alternative plant-based protein ingredients. Also starch can be an important “binder” to help achieve pellet durability.

Firstly, realise that starch does not truly “gelatinise” during extrusion – there is not enough water present for the swelling and unravelling of granules that characterise the gelatinisation reaction. In addition, the starch is easily damaged by excessive “shear” during extrusion. So we promote conditions that will “cook” the starch – achieving sufficient temperature with sufficient water, and with sufficient time, but without excessive shear – therefore use of a preconditioner can be a major advantage.

Another option – if we require starch for pellet binding – is to choose a starch that cooks and binds more effectively at a lower temperature – such as use of tuber starches instead of grain starches. Therefore effective selection of both the source and the amount of starch can be used to optimise the processing and nutritional characteristics of the product formulation.

Protein

During extrusion, the protein denaturation reaction is not unlike that of starch – that is, with respect to good “functional” protein (here referring to protein functionality from a physical, rather than nutritional, perspective). The globular proteins unravel and, under the right conditions (optimal moisture content and temperature), can cross-link. Therefore “functional” protein contributes to binding and pellet durability. But many of the traditional fish meals, while good nutritionally, contain denatured protein, and contribute little to the “binding” function.

So while the scarcity of traditional marine proteins (eg fish meals) is an issue for nutritional balance, the substitution of “functional” plant proteins can have the added benefit of assisting pellet durability – as long as the process promotes rather than destroys that functionality (temperature and shear not excessive).

Fat

Fat under normal extrusion conditions is stable – it does not itself change and “cook” as starches and proteins do. But it does have a major effect on the extrusion process – increasing “slip” and effectively lowering viscosity, and therefore affecting expansion/density, extruder backfill/degree of cook, and pellet durability. An increase in fat content of the mix of only two percent (which can happen due to raw material variations) has a similar effect on the effective viscosity of the melt as a five percent increase in moisture content. Therefore control of fat content can be a major issue.

At the same time, for most species, as high a fat content as possible is required for nutrition (feed energy). This is where one of the tensions lie – the challenge of achieving good stable pellets at sufficiently high fat content. Strategies to achieve this balance include the use of appropriate extrusion systems (twin screw extruders can operate in a more stable manner to higher fat levels than single screw extruders), and methods to maximise post-process addition of oil, such as vacuum infusion.

There are of course many other aspects of ingredients that also need to be balanced in successful feed extrusion.

Density control

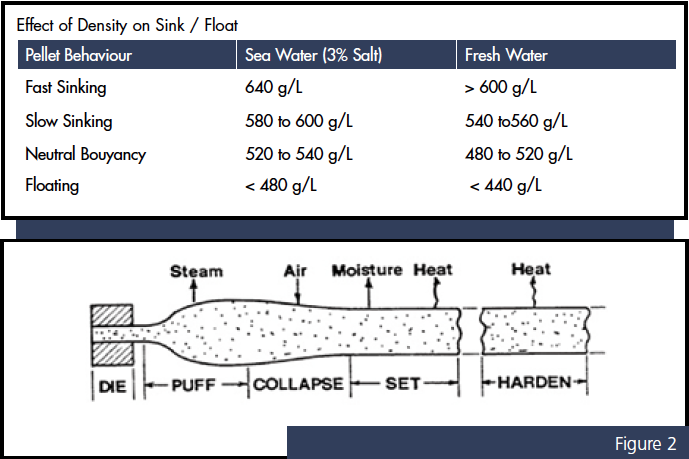

The finished product bulk density is one of the key product quality attributes, as it directly influences the sink / float behaviour of the finished product. Note, however, that this does not only relate to the extrusion process – eg drying also affects pellet density. In fact, drying under inappropriate conditions can result in drying and shrinkage of the outside layers, increasing overall density so the pellet sinks (eg as required). Then, over time in storage, moisture redistributes within the pellet, the outside layers relax and expand, and the feed turns from floating to sinking.

The bulk density is the result of the balance between the expansion (influenced by the process conditions and the amount and type of starch) and elastic collapse (influenced by the amount and type of protein). That is, again there is a complexity in the extrusion process which makes it inherently difficult to predict and control. Under the correct conditions:

In addition:

Degree of Expansion = f { Melt Temperature (TM), Die Pressure Drop (DPd) }, with the Melt Rheology and the Die Geometry greatly affecting DPd.

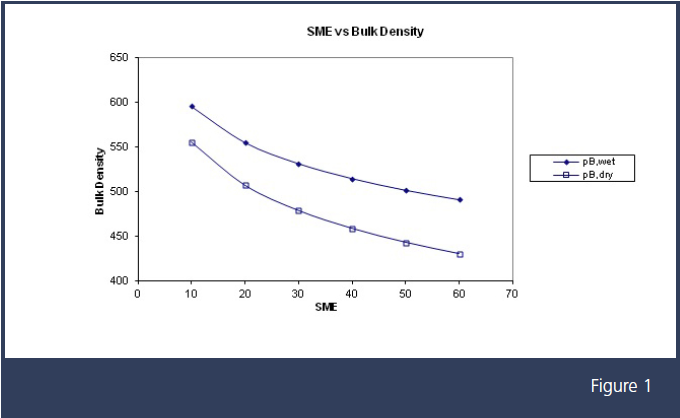

The product bulk density is also significantly influenced by the Specific Mechanical Energy (SME), since the SME directly affects TM and also affects the molecular degradation of the starch and the proteins – which changes the viscosity and elasticity of the melt. Figure 1 shows some measured results of bulk density vs SME.

The SME is influenced by process parameters, most significantly the melt moisture content (used to manipulate the melt rheology), the screw profile design, and the screw speed.

Aquafeed specifications – not the full story

Final product nutrition (and FCR) is not just due to the composition of the formulation ingredients – though that is what feed specifications almost exclusively (along with density) often dictate.

The manufacture of a feed should be considered as

Formulation + Process ----> Product

The ingredient source (and the order of addition) have a significant impact upon the product nutrition. For example, the effect of oil added during the process is not the same as oil added via external coating – complexes formed during extrusion can change the nutritional effect of the oil.

Energy inputs also have a major role in final nutrition of the feed. Energy may be added via Convective Energy (steam injection), Thermal Energy (barrel heating) and Mechanical Energy (viscous dissipation or SME). The comparative balance of these energy inputs affect nutrition by changing the conversion and break-down of proteins and starches, changing their nutritional contribution. In extreme cases, it can even form fat complexes that are toxic to fish.

When considering Convective Energy, the role of process time is also critical. This is the basis of preconditioning, which allows extended time to initiate the cooking of starches and proteins.

Conclusion

Extrusion is not a simple process. The interactions that occur in process parameters, along with variations in raw materials and changes over time due to extruder and die wear, makes it a difficult process to control. And these variations can have “invisible” effects – because nutritional content of the formulation does not fully define the nutritional performance of the feed. Variations in the extrusion process do not only affect physical changes in the product such as density and size/shape, it also affects the way in which the fish will digest the ingredients. A good understanding of the extrusion process – and well-defined process parameters to guide operators – is required for reliable and consistent feed production.

Read the magazine HERE.

First published in International Aquafeed, March-April 2015

Extrusion technology provides a number of major benefits over the more traditional pellet milling processes commonly used for aquaculture feeds. In particular, extrusion can provide a much higher degree of control over the “cook” achieved, as well as better control of the product density (therefore controlling the floating/sinking characteristics).

But extrusion is a very complex process – and we only have “indirect” control over that process. That is, we have full control over some variables – eg screw speed and amount of water added. But there are other inputs over which we have “limited” control. For example, we specify a formulation, and within limits we control the specifications of ingredients that go into it – but ingredients do vary, so our process needs to cope with “normal variation”. We set up the extruder and die to a known configuration – but the machine and the die-plate wears, so that over time the process changes.

In addition, we never get just one parameter changing during extrusion – if ingredients vary, it doesn’t just change the final product composition – it changes the rheology of the mix and therefore changes how the melt moves through the extruder and the die, which in turn affects the residence time and temperature developed in the melt, which changes degree of cook and expansion – and therefore affects digestibility and floating/sinking characteristics. Within this complex relationship, we need to achieve consistency – of nutrition, of digestibility, of physical characteristics. It is the cumulative effect of these parameters which ultimately determine the feed conversion ratio (FCR) for the product.

So to use extrusion effectively – and take full advantage of the opportunities offered by the technology – the extrusion process needs to be properly understood. This article discusses just a couple of the issues relating to successful extrusion of aquafeeds.

Extrusion chemistry & aquafeed ingredients

In the area of ingredients, the aquafeeds industry faces a series of contradictions. Marine meals provide the best nutritional basis, but are increasingly difficult to obtain and are therefore expensive. Selected plant sources of protein can provide required proteins, but tend to come with fibre and starch which can interfere with the extrusion process and affect digestibility. We generally require very high fat (energy) contents in the feeds – but high fat levels are a problem in extrusion. Following are some basics of “extrusion chemistry” that relate to the way we design aquafeed extrusion processes:

Starch

Many fish species do not tolerate starch – especially uncooked starch. But starch comes with many of the alternative plant-based protein ingredients. Also starch can be an important “binder” to help achieve pellet durability.

Firstly, realise that starch does not truly “gelatinise” during extrusion – there is not enough water present for the swelling and unravelling of granules that characterise the gelatinisation reaction. In addition, the starch is easily damaged by excessive “shear” during extrusion. So we promote conditions that will “cook” the starch – achieving sufficient temperature with sufficient water, and with sufficient time, but without excessive shear – therefore use of a preconditioner can be a major advantage.

Another option – if we require starch for pellet binding – is to choose a starch that cooks and binds more effectively at a lower temperature – such as use of tuber starches instead of grain starches. Therefore effective selection of both the source and the amount of starch can be used to optimise the processing and nutritional characteristics of the product formulation.

Protein

During extrusion, the protein denaturation reaction is not unlike that of starch – that is, with respect to good “functional” protein (here referring to protein functionality from a physical, rather than nutritional, perspective). The globular proteins unravel and, under the right conditions (optimal moisture content and temperature), can cross-link. Therefore “functional” protein contributes to binding and pellet durability. But many of the traditional fish meals, while good nutritionally, contain denatured protein, and contribute little to the “binding” function.

So while the scarcity of traditional marine proteins (eg fish meals) is an issue for nutritional balance, the substitution of “functional” plant proteins can have the added benefit of assisting pellet durability – as long as the process promotes rather than destroys that functionality (temperature and shear not excessive).

Fat

Fat under normal extrusion conditions is stable – it does not itself change and “cook” as starches and proteins do. But it does have a major effect on the extrusion process – increasing “slip” and effectively lowering viscosity, and therefore affecting expansion/density, extruder backfill/degree of cook, and pellet durability. An increase in fat content of the mix of only two percent (which can happen due to raw material variations) has a similar effect on the effective viscosity of the melt as a five percent increase in moisture content. Therefore control of fat content can be a major issue.

At the same time, for most species, as high a fat content as possible is required for nutrition (feed energy). This is where one of the tensions lie – the challenge of achieving good stable pellets at sufficiently high fat content. Strategies to achieve this balance include the use of appropriate extrusion systems (twin screw extruders can operate in a more stable manner to higher fat levels than single screw extruders), and methods to maximise post-process addition of oil, such as vacuum infusion.

There are of course many other aspects of ingredients that also need to be balanced in successful feed extrusion.

Density control

The finished product bulk density is one of the key product quality attributes, as it directly influences the sink / float behaviour of the finished product. Note, however, that this does not only relate to the extrusion process – eg drying also affects pellet density. In fact, drying under inappropriate conditions can result in drying and shrinkage of the outside layers, increasing overall density so the pellet sinks (eg as required). Then, over time in storage, moisture redistributes within the pellet, the outside layers relax and expand, and the feed turns from floating to sinking.

The bulk density is the result of the balance between the expansion (influenced by the process conditions and the amount and type of starch) and elastic collapse (influenced by the amount and type of protein). That is, again there is a complexity in the extrusion process which makes it inherently difficult to predict and control. Under the correct conditions:

- Higher amylose starch content makes the extrudate expand more at the time of exiting the die

- Higher “functional” protein makes the melt more elastic, so it recoils after the initial expansion and starts to collapse

- Higher amylopectin starch increases the “solidification” temperature of the melt, which determines how far the melt recoils before the structure hardens.

In addition:

Degree of Expansion = f { Melt Temperature (TM), Die Pressure Drop (DPd) }, with the Melt Rheology and the Die Geometry greatly affecting DPd.

The product bulk density is also significantly influenced by the Specific Mechanical Energy (SME), since the SME directly affects TM and also affects the molecular degradation of the starch and the proteins – which changes the viscosity and elasticity of the melt. Figure 1 shows some measured results of bulk density vs SME.

The SME is influenced by process parameters, most significantly the melt moisture content (used to manipulate the melt rheology), the screw profile design, and the screw speed.

Aquafeed specifications – not the full story

Final product nutrition (and FCR) is not just due to the composition of the formulation ingredients – though that is what feed specifications almost exclusively (along with density) often dictate.

The manufacture of a feed should be considered as

Formulation + Process ----> Product

The ingredient source (and the order of addition) have a significant impact upon the product nutrition. For example, the effect of oil added during the process is not the same as oil added via external coating – complexes formed during extrusion can change the nutritional effect of the oil.

Energy inputs also have a major role in final nutrition of the feed. Energy may be added via Convective Energy (steam injection), Thermal Energy (barrel heating) and Mechanical Energy (viscous dissipation or SME). The comparative balance of these energy inputs affect nutrition by changing the conversion and break-down of proteins and starches, changing their nutritional contribution. In extreme cases, it can even form fat complexes that are toxic to fish.

When considering Convective Energy, the role of process time is also critical. This is the basis of preconditioning, which allows extended time to initiate the cooking of starches and proteins.

Conclusion

Extrusion is not a simple process. The interactions that occur in process parameters, along with variations in raw materials and changes over time due to extruder and die wear, makes it a difficult process to control. And these variations can have “invisible” effects – because nutritional content of the formulation does not fully define the nutritional performance of the feed. Variations in the extrusion process do not only affect physical changes in the product such as density and size/shape, it also affects the way in which the fish will digest the ingredients. A good understanding of the extrusion process – and well-defined process parameters to guide operators – is required for reliable and consistent feed production.

Read the magazine HERE.

The Aquaculturists

This blog is maintained by The Aquaculturists staff and is supported by the

magazine International Aquafeed which is published by Perendale Publishers Ltd

For additional daily news from aquaculture around the world: aquaculture-news

No comments:

Post a Comment